The Ledger

Curated content foranalytical business leaders

Tag Archives: Process Manufacturing

Modern Manufacturing is On the Rise

There is a huge amount of innovation happening in manufacturing regarding the type of the products being designed (which are helping address some of the sustainability and environmental issues) and the processes to manufacture and sell them. Manufacturers are leading the pack of companies that are transforming their businesses, driving innovation, and winning in the digital economy. By leveraging dynamic technologies, leading manufacturers are expanding their reach to new competitive avenues and new opportunities to deepen relationships with customers and supply chain partners. The intelligent enterprise concept provides the blueprint for companies in the industrial manufacturing industry to optimize, extend, and transform their businesses.

Read More at The Digitalist by SAP >

Manufacturers Are Shifting from Being Preventative to Predictive

For many manufacturers today, the focus of their business is not so much producing products for sale as it is delivering better business outcomes for their customers through asset-as-a-service offerings. Leading organizations use an intelligence-based approach, where maintenance teams monitor conditions in real time using an enterprise asset management tool. For asset manufacturers, real-time analytics and predictive maintenance create the opportunity for entirely new business models. In the past, manufacturers made the assets and customers operated them. Today, these boundaries are blurring as manufacturers leverage new asset-as-a-service business models and deliver outcomes rather than just the physical assets.

Read More at Forbes Magazine >

Advanced Visibility and Collaboration Creates Efficient Manufacturing Processes

In today’s competitive environment, companies are always looking for ways to differentiate themselves from the competition and improve the customer experience. For machinery, equipment, and asset manufacturers, this often starts with developing smarter products to capture more information about how they are operating and performing around the globe. A large German machinery manufacturer found that as their global customer base grew, they needed to find a way to improve transparency across their products, while improving visibility and transparency into pump and component details globally. By leveraging a technology that promoted company-wide collaboration and visibility, they were able to become more efficient and reduce overall risks of their business.

Read More at The Digitalist by SAP >

Breaking Down the Barriers of Personalized Cost Visibility in Manufacturing

Customers are ever-evolving and gravitating towards more personalized products that meet their unique specifications. For manufacturers, meeting this demand for high-quality individualized goods is nearly impossible to do in a cost-efficient manner with outdated operational processes based on yesterday’s technology. Therefore, organizations are looking to transform their facilities into open integrated factories – the kind that enable the visibility and flexibility needed to make their customers’ personalization dreams come true. By adopting integrated and dynamic technologies, manufacturers can break down these barriers, connect their processes, and achieve a unified view of the essential information required to improve production performance.

Read More at The Digitalist by SAP >

Next-Generation Manufacturing Processes Are Here to Stay

Industrial machinery and component manufacturers are stretched thin, addressing global challenges like the need for clean energy, smart cities, and a circular economy. In addition, they are confronted with ever more demanding customers and the transformation of their business ecosystem, including customers, partners, and competitors. Innovative industrial machinery and component manufacturers are tackling these challenges by pursuing new business models based monetizing data assets. These companies are embracing new technologies as they focus on strategic priorities to drive digitalization. These strategies are helping them realize their vision.

Read More at The Digitalist by SAP >

Is Activity-Based Costing Worth It?

Manufacturing companies need to understand product costs accurately and in detail. This kind of information is essential for planning operations, pricing, and evaluating business margins. Activity-based costing helps manufacturers identify what products are truly profitable, the true costs of products for pricing, and what activities are driving costs. However, activity-based costing is known for being difficult to apply and labor-intensive due to the extensive data needs of the process. The trick to knowing if activity-based costing is worth the trouble is first finding a tool that can compute accurate product costs and has the capabilities to take the labor and data needs off your hands.

Read More at The Business Case >

New Solutions Are Necessary For Success In Chemical Manufacturing

The chemical industry is characterized by process-based manufacturing, high capital intensity, and long investment cycles. Over the longer term, capital is deployed for R&D or capacity expansion, while, over the shorter term, resources are targeted to increase productivity and reduce costs. This process has kept the industry stable because their conservative response to change was sufficient. Over the last several decades, however, the pace of change outside the firm’s sphere of control has been unprecedented. Changes in regulation, competition, supply, demand, and technology pose greater chances for disruption in ever shorter periods of time. At some point, a company’s inability to respond within an acceptable window to the pace of change of external factors will begin to exponentially add risk.

Read More at The Digitalist by SAP >

Haven’t Joined the Industry 4.0 Transformation? It’s Not Too Late

We’re in the midst of a significant transformation regarding the way we produce products thanks to the digitization of manufacturing. This transition is so compelling that it is being called “Industry 4.0” to represent the fourth revolution that has occurred in manufacturing. Finance professionals know that new technologies will fulfill the promise of artificial intelligence, data analytics, and cognitive technologies, and will eventually lead to the development of global systems that create dramatic efficiencies and enable business leaders to make more informed integrated decisions. But at this point, manufacturers who haven’t figured out how to apply Industry 4.0 across their companies aren’t yet falling behind, and they’re far from alone.

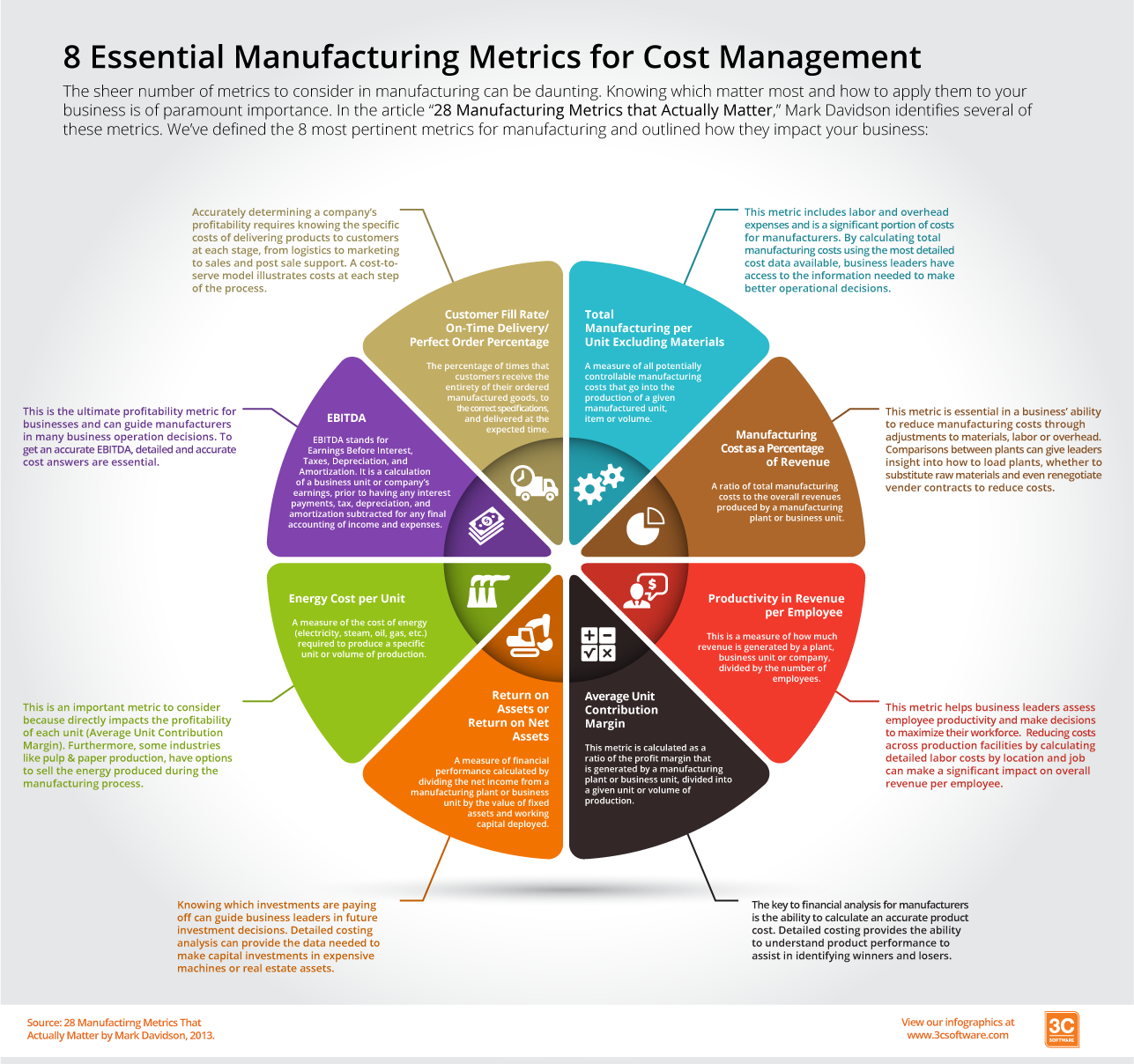

8 Essential Manufacturing Metrics Infographic

The sheer number of metrics to consider in manufacturing can be daunting. Knowing which matter most and how to apply them to your business is of paramount importance. In the article “28 Manufacturing Metrics that Actually Matter,” Mark Davidson identifies several of these metrics. We’ve picked the 8 most pertinent metrics for manufacturers and outlined what they mean and what they mean for your business in the following infographic.

The 8 metrics captured here are just the start of the many data points you must understand to effectively manage your costs and profits. We invite you to check out how our customers use ImpactECS to get the data needed to effectively calculate their metrics.