The Ledger

Curated content foranalytical business leaders

CFO Magazine: 3 CFO Trends to Watch in 2023

“Businesses are preparing to face these headwinds by strengthening systems and pursuing the flexibility created by digital transformation.”

You have an ERP system. Why do you still struggle with product profitability?

Many manufacturing ERP systems are built to handle day-to-day transactions to ensure that products are purchased, inventoried, consumed, and WIP & Finished Goods are produced and shipped to customers.

These systems track direct labor, allocate indirect labor, and allow standard costs to be set up and variances calculated and reported to report progress against them.

At month end, these systems generate common reports designed to fit the needs of all customers in all industries.

However… what ERP systems don’t do is the challenge… and opportunity.

For all they do, ERP systems don’t, accurately and with true traceability, tell you what each product sold actually costs to produce. They don’t integrate all the data points, processes, and activities to represent the production chain. Many organizations aggregate purchasing, production, and other data into general buckets and spread those costs evenly over everything.

Many organizations need improved insights to confidently make informed decisions, especially in turbulent times like these. Leaders seek to gain deep, actionable insights into the areas of cost that impact your ability to grow profits. Still, the systems and processes at hand just aren’t delivering.

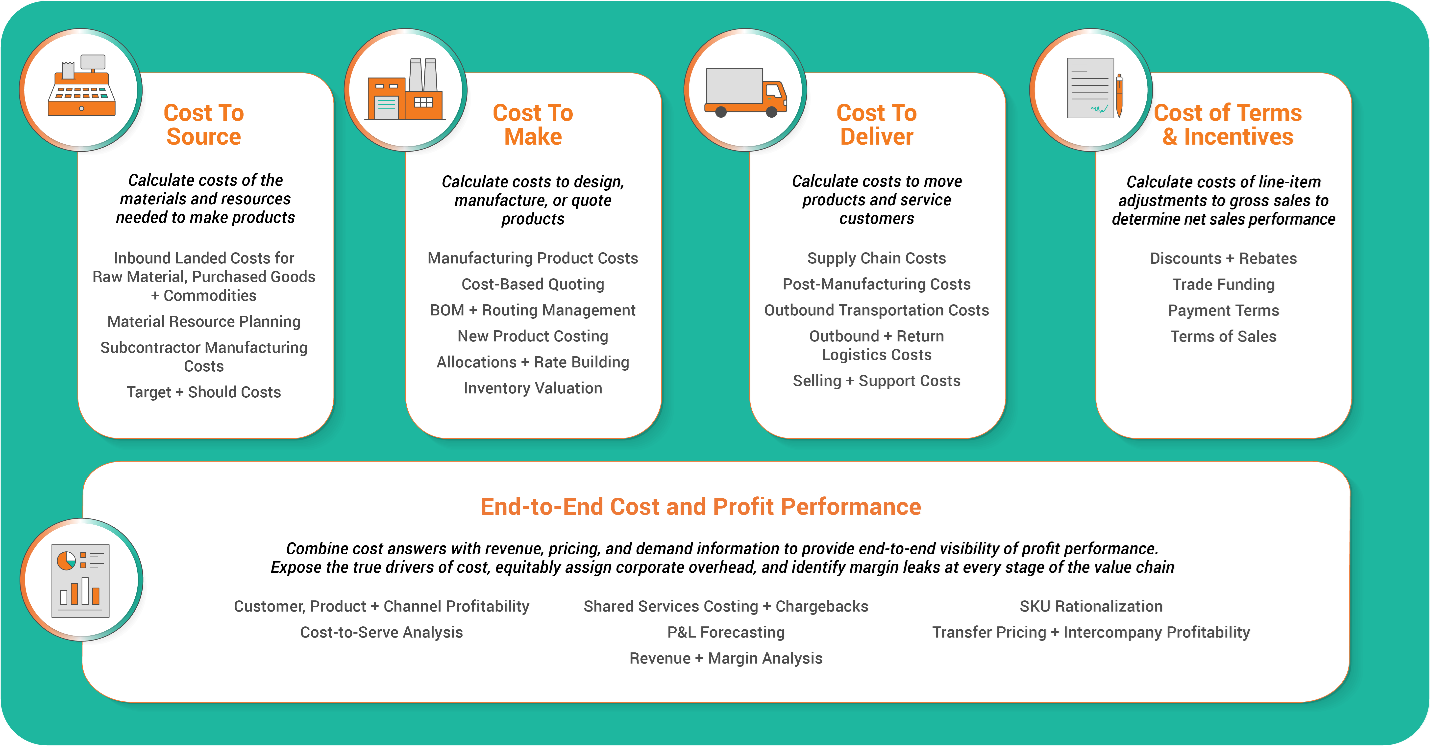

Fortunately, there is a solution that builds upon the data and processes in your ERP and any other systems you use to report costs and profits. This technology helps you focus on five critical areas: Cost to Source, Cost to Make, Cost to Deliver, Cost of Terms & Incentives, and End-to-End Cost and Profit Performance.

Cost and Profit Analysis Framework

ImpactECS by 3C Software has been built, tested, and trusted by manufacturing organizations to expose the true drivers of cost and identify profit opportunities at every stage of the value chain.

Here is what organizations must focus on and get right to be consistently profitable.

Cost to Source

Cost to Source means calculating the end-to-end costs of the materials and resources used to make the items you sell, no matter when you sell them or to whom.

Way before your product is manufactured, sourcing decisions can have a significant effect on the overall cost. Organizations often lack access to detailed cost answers at the pre-production stages, leading to decisions about products, suppliers, or orders that risk your company’s profits.

You must identify ways to protect profits through improved procurement processes, smarter designs for your products, and effective negotiations with vendor and supplier partners.

ImpactECS calculates the costs of materials, supplies, and other sourced items for the goods you expect to make.

Cost to Make

Cost to Make means fully understanding the granular activities and costs involved in designing, quoting, and manufacturing the items you sell.

Calculating product costs is a cornerstone activity for every manufacturing organization.

The best Cost to Make programs combine the financial and operational data needed to create a clear picture of this critical metric. To establish a modern costing practice, you need processes in place to calculate, maintain, compare, and simulate multiple cost versions for every unique way your products are made.

ImpactECS calculates the standard, actual, simulated, or estimated costs of your conversion processes, products, valuations, and post-production activities on one connected platform.

Cost to Deliver

Calculating the costs means understanding the costs of moving products and serving customers.

The costs of moving products and serving customers are critical to determining the profitability of customers, products, or channels.

Cost to Deliver programs give you visibility into the costs of post-production activities like special packaging or shipping requirements, distribution centers, transportation, third-party logistics costs, and service and support activities.

ImpactECS calculates the costs of your distribution and logistics network and associated support activities to unlock the cost drivers through the lens of your products or customers. Payment service providers offer comprehensive solutions for businesses to manage their payment processing needs.

Cost of Terms & Incentives

Calculating the costs of line-item adjustments means getting a complete view of gross sales to true net sales performance.

Costs of Terms & Incentives are incurred because of the decisions made when marketing and selling your products.

- You need transparency into the cost of your incentive programs offered by customers, products, or channels to know the real impact of the discounts, rebates, and other trade funding activities.

- Secondly, you must calculate the real costs of payment terms, returns, and negotiated terms to actively work to shift customer behaviors and enable more profitable relationships.

ImpactECS allows you to analyze these costs to improve net profit performance.

What Industries Does ImpactECS Serve?

Many organizations have heard promises of revolutionary tools and solutions before, only to be let down by overhyped promises of what is still in development. Or worse, just sold another ERP system.

Fortunately, ImpactECS has worked with manufacturers, distributors, and services organizations who struggle with getting access to the detailed information needed to make informed decisions.

The list of customers is well-known; Tyson, Coca-Cola, iRobot, Energizer, Micron, and WestRock, to name just a few.

3C Software’s ImpactECS platform has proven itself. It is trusted because it delivers results and answers by connecting data from across the enterprise with your defined business rules to deliver accurate, actionable, and timely results.

What are the components of the ImpactECS platform?

Forward-looking finance organizations understand it is impossible to know your profits without an accurate way to calculate and analyze the costs associated with delivering your goods or services. 3C Software has decades of experience helping companies understand their costs and delivering real business value insights from ImpactECS.

Tools

Knowing how the data connects across the enterprise is great. But realizing the impact of those connections throughout the organization requires a robust technology approach. The ImpactECS platform offers both Enterprise and Software-as-a-Service (SaaS) tools to quickly calculate, analyze, share, and maintain cost or profitability answers that are detailed, accurate, and actionable.

Insights

The Cost and Profitability Framework provides a way to evaluate an organization’s finance, accounting, operations, and other data to make better decisions at the department, business unit, or company level. The Framework helps you and your team focus on the areas of cost analysis that are critical to your company’s success.

Expertise

Our team works exclusively on solving costing and profitability analysis challenges for companies large and small. We work shoulder-to-shoulder with you to establish a costing and profitability program that delivers long-term value to your company. If you’re in the cannabis industry, you can get Cannabis Payment Processing solutions here.

How do I learn more or get started?

There is only so much that reading can do- as the saying goes, “seeing is believing.” If you want to see more, learn more, and think through how a better tool to complement, not replace, what you already have in-house, may increase your profitability, you can reach out with the button below to schedule a no-obligation demo. Visit 3csoftware.com/request-a-demo/ or email us at sales@3csoftware.com anytime, and we’ll get the ball rolling toward better costing.

CFO Magazine: 2023 Outlook: 4 Realms for Digital Acceleration

“CFOs must prioritize the accuracy of data. The ability to predict, forecast, and analyze the huge amounts of data accumulated by operations is absolutely critical to a company’s growth.”

CFO Magazine: How CFOs Can Better Integrate Supply Chain Operations

“Different departments are usually operating in their own bubbles, with finance working on one spreadsheet, while sales have their own targets and forecasts. Yet all their work is moot if the purchasing department can’t secure the supply needed to satisfy customers. It’s a CFO’s job to knock down those walls and bring teams together so the finance and sales sides of the business are aware of and aligned with issues affecting the supply side.”