The Ledger

Curated content foranalytical business leaders

Tag Archives: ERP

Business Modeling & Analytics: Creating Value Requires the Right Technology

Evergreen writer Eric Jorgenson declares “the purpose of the institution of business is to create and deliver value in an efficient enough way that it will generate profit after cost.” If only it were as simple as it sounds! It’s bigger than checking boxes to produce reports, closing the books each period and remaining in compliance. To create real value, forward-looking finance organizations have moved beyond traditional finance activities and are establishing robust business modeling & analytics programs that provides detailed visibility into historical performance and expected results.

Establishing a Robust Business Modeling & Analytics Program

Companies are increasingly dependent on automation and analytics to deliver clear, actionable and forward-looking insights. With the explosion of available data from quickbooks desktop canada and the need to quickly evaluate it, finance teams are centered on two areas – the data and the models. Additionally, businesses who need help with web design services may consult this professional web designer dallas.

❶ Integrating data and accessing results:

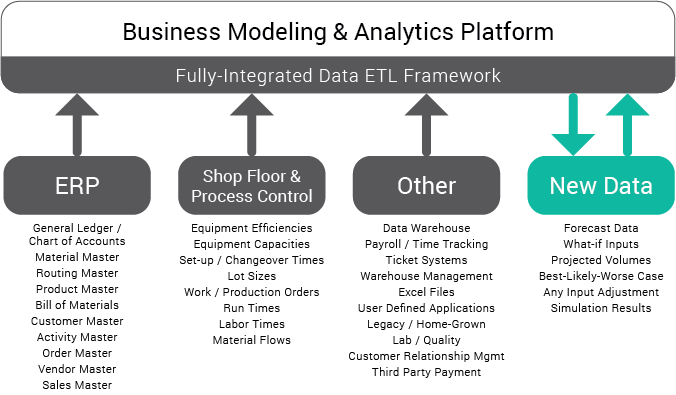

As the size of the organization grows, so do the number of systems that support it. Companies can have hundreds of machines that generate endless data points along with groups of data warehouses, BI systems and other data sources holding information. Without a way to link data across the enterprise, it’s impossible to deliver meaningful insights or accurate results.

One shortcoming of most business analytics programs is the inability to integrate forecasted or simulated data as part of the modeling data set. Along with the expected data from ERP, shop floor and other systems, advanced analytics program recognize the need to retain and use forecasted or simulated data alongside historical data to predict performance and test assumptions for any data combination.

❷ Building models and running simulations:

The best models and simulations reflect real-world scenarios, not a pre-defined process or methodology, and delivers results in a timely manner. They must include measurable and meaningful KPIs that expose improvement opportunities and encourage behaviors that positively effect performance.

What is an integrated modeling platform, and why do you need one?

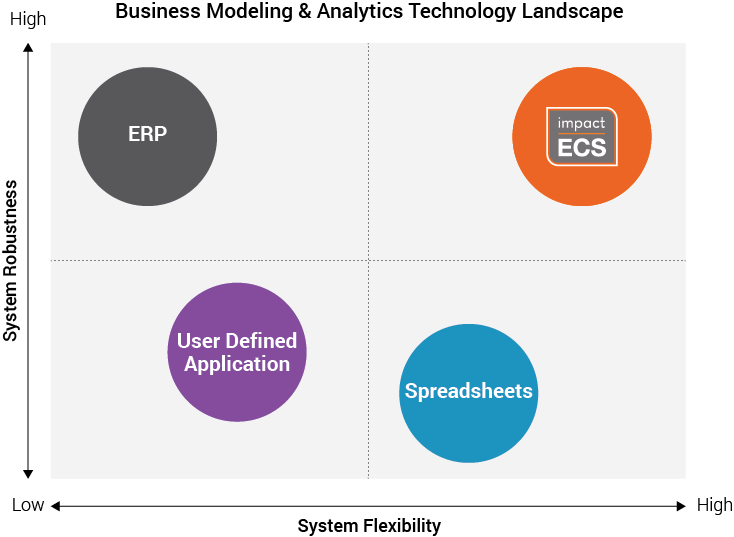

Most organizations have a few “system types” that provide, calculate, or share data as part of the planning and analytics process. The Business Modeling & Analytics Technology Landscape compares the different technologies and their attributes. The vertical axis measures the robustness of the system – or its ability to handle very large data sets and the ability to execute large sets of calculations quickly. Also, robust systems are scalable and can handle multiple users and permission sets. On the horizontal axis, the flexibility of the system represents the ability for the system to be configured to meet the company’s unique needs, both now and in the future.

Business Modeling and Analytics “System Types”

ERP: The ERP system is the system of record for organizations and serves as the transactional system. They are often limited by the design choices in the initial implementation, creating a rigid environment with no inherent simulation capabilities.

User Defined Applications: Many companies try to meet their analytical needs with applications developed internally. From legacy systems dating back to the 70s to AS400 and Access databases, User defined applications offer customized solutions, but their capabilities are often a reduced or partial set of controls. Additionally, simulation capabilities are limited to the programmed options, and changes to the system require IT involvement in maintaining and upgrading systems.

Spreadsheets: Desktop modeling tools solve a variety of challenges when it comes to creating a flexible modeling environment. It isn’t however, a system. That means limited controls and auditability will assure integrity issues. Further, spreadsheets are unable to scale with the requirements to build a robust modeling and analytics environment, and has difficulty handling larger sets of data.

Integrated Business Modeling & Analytics Platform: ImpactECS is an integrated modeling & analytics platform that leverages data from existing systems and delivers complete flexibility to design, calculate, manage, and report results that drive results by creating value. With a centralized approach, finance and planning organizations can link important data from across the company and build models to calculate, predict, or simulate performance at any level of detail or business dimension.

Each of these system types are critical and offer valuable benefits that keep the business running. However, organizations on a mission to create real value through analytics need to augment their IT footprint with technology that delivers the best of both worlds – a solid, enterprise-level system that connects relevant systems and data, and a flexible modeling platform to build, run, and maintain models that meet the company’s unique business requirements. Companies build models with ImpactECS for everything from detailed manufacturing product costs, cost-to-serve and distribution costs, and profitability analytics for any business dimension.

Visit us at www.3csoftware.com to learn more.

How Does Enterprise Costing with ImpactECS Enhance Your ERP System – Part 1

When we approach companies to discuss the value of implementing an enterprise cost solution like ImpactECS, we are often asked to describe the difference between our solution and a traditional ERP system. In this three-part article, we’ll discuss the ways that enterprise costing can enhance your ERP system and put your company on the path to better costing.

First up – rate building.

We talk to controllers and cost accountants every day and it never fails that when we ask how they calculate rates, they inevitably respond that they use their ERP system. We’re always curious how they accomplish this task because we’ve never seen it done before. And that’s when the truth comes out. They’re calculating the rates in a spreadsheet and inputting the information into their ERP system.

To calculate an overhead rate, you need two things – a pool of indirect costs and an allocation method, or driver. In complex environments you can have hundreds of rates. And while the math is not complicated, pulling together all of the components can be a cumbersome task.

So what’s so special about calculating rates using an enterprise cost system like ImpactECS?

I’m glad you asked! With ImpactECS, whenever you change a factor or driver used in a rate calculation, you can automatically restate the costs, inventory values, budgets, or variances connected to the rate. For example, if you increased the machine efficiency rate on a particular production line, you would immediately see the reduced cost per unit of the products manufactured on that line without having to manually intervene.

That’s great, but I still need the rates in my ERP system!

Never fear! By connecting ImpactECS with your ERP system, you can continue to upload rates as you’ve done in the past to perform other transactional processes that depend on these rates.

Stay tuned for Part 2 where we’ll talk about the integration of disparate systems with ImpactECS.

ERP Implemeneters: Stop Reinventing the Costing Wheel

Have you ever advised your customer to customize their erp software? If you’ve been involved in at least one ERP implementation, the answer to that question is probably “yes”. But the first question you should ask before recommending customization is whether the problem you’re solving is tactical or strategic. For tactical or customary processes like purchasing or warehousing, there is little need to make significant modifications to the ERP system. But for strategic processes that can affect the company’s ability to compete, there is a tendency to look toward customization. For process and complex manufacturers, cost accounting is one of those strategic processes that can make or break a company’s ability to be competitive in the market place.

As an ERP implementer, you know that customizing an ERP module can be a time consuming and expensive proposition that will potentially prohibit your customer from taking advantage of future upgrades and maintenance. Even after the pricey modifications, companies who have complex manufacturing processes are still likely to turn to spreadsheets or attempt to build external systems to do the real analysis necessary to run the business effectively. ImpactECS has become the costing system of choice for many process manufacturers because it can handle detailed costing processes while limiting or eliminating the need for ERP customization, spreadsheets or custom development.

As an ERP implementer, you know that customizing an ERP module can be a time consuming and expensive proposition that will potentially prohibit your customer from taking advantage of future upgrades and maintenance. Even after the pricey modifications, companies who have complex manufacturing processes are still likely to turn to spreadsheets or attempt to build external systems to do the real analysis necessary to run the business effectively. ImpactECS has become the costing system of choice for many process manufacturers because it can handle detailed costing processes while limiting or eliminating the need for ERP customization, spreadsheets or custom development.

With ImpactECS, many of our customers have expanded their ability to perform challenging cost accounting tasks in a fully integrated environment. Don’t believe us? Here are a few examples of world-class manufacturing companies from very different industries that selected ImpactECS to handle their costing instead of customizing their ERP systems:

Paper producer, Domtar Inc., has grown through a number of acquisitions and ended up with a scenario that many companies face – multiple instances of SAP in different parts of the company. Complicating the situation even further was the fact that there were different costing methodologies employed in the different locations, making comparisons and performance management nearly impossible. Instead of choosing to start from scratch by customizing a new SAP costing tool, they selected ImpactECS as a way to both create a standard methodology and bridge the two instances of SAP to manage all of their costing data in one centralized location.

Tyson Foods, one of the leading poultry processors in the United States, faced some more unique problems when attempting to calculate product costs using SAP. The disassembly process, when a live bird is portioned into individual pieces, has lots of complexities that a traditional ERP cost module is not equipped to handle. Since ImpactECS’ model building capabilities is flexible enough to mirror any process, Tyson was able to develop a very detailed costing system that allows them to perform advanced variance analysis. In addition, the commodity nature of their product requires the ability to calculate a daily actual cost so they can price their products appropriately in the market and ensure that they remain competitive.

Understanding the changing prices of raw inputs is a critical need for process manufacturing companies like potato giant, J.R. Simplot. Chances are that if you had an order of fries at lunch today, Simplot produced them. Prior to ImpactECS, Simplot used JD Edwards along with a full complement of spreadsheets to establish their standard product costs. This month-long, manual process was reduced to a fully-automated process that only takes matter of hours to perform. Beyond product costing, Simplot uses ImpactECS to analyze scenarios like “What happens to my product costs if the price of cooking oil goes up 5% next quarter?” Instead of an analyst spending hours building a standalone spreadsheet that is likely based on faulty logic and incomplete data sets, ImpactECS has the tools to run what-if scenarios using the same logic and data used for product costing. The result is more confidence in the results and a better tool to make decisions.

The semiconductor industry has a unique set of costing challenges due to the complexity of their manufacturing process and the lifespan of their products. Analog Devices uses ImpactECS as its costing platform because it provides granular cost results at every WIP point in their fabrication process. By combining production data from PROMIS, spending information from SAP and costing logic stored in ImpactECS, Analog developed a completely automated costing process with a common methodology that works for their seven manufacturing facilities. Beyond costing, Analog Devices has expanded the use of ImpactECS beyond product costing by building a subcontractor pricing engine within their costing system. Analog now has visibility into standard costs at the vendor level to accurately develop budgets, track subcontractor spending, and make decisions on how and when to outsource parts of their manufacturing process.

So, what makes more sense? (A) Asking your customer to commit time and resources to a customization project that will ultimately cost more and deliver less, or (B) looking to ImpactECS to get a fully integrated costing tool that can enhance your customer’s ability to make better operational decisions. If you’ve chosen B, then we invite you to learn more about the ImpactECS Enterprise Cost System by visiting www.3csoftware.com.

It’s the Cost!!!

Today I met with finance and operations managers for a manufacturing company that didn’t really understand the unique costs of each product they produce. As a result, they weren’t really sure of the margins being created by each product and customer they serve. The interesting part was that these very same managers were pondering whether they could afford to invest in a costing system. As I listened I couldn’t help but wonder, “How can you NOT afford to invest in a costing system? Doesn’t everyone know that a true and accurate understanding of your product costs is paramount to the success of a competitive, commodity business? “

As the meeting continued, topics like capacity utilization, fixed cost absorption, and the need to produce forecasted costs based on future period sales forecasts and radically changing raw material prices came up. The voice inside my head yelled, “How can you NOT afford to invest in a costing system?” Admittedly and shamefully adopted from the political arena, I too often find my inner cost accountant shouting IT’S THE COST STUPID!, and right then I knew the name of my blog.

At the heart of any successful commodity-goods manufacturer is a cost-focused culture that understands and embraces this mantra. In these challenging economic times – arguably more so than in better times – a full understanding of the true and accurate costs incurred at the unique product level are of utmost importance. In fact, this data truly creates a competitive advantage in the market place. True and accurate costing data that allows me to decide where best to produce my products, which of my production lines to set idle, which orders and price points to accept and which to reject, gives me an advantage over a producer that doesn’t share the same level of cost insight. Without this insight my seemingly correct answers to these questions could lead me in the exact wrong direction. A seasoned cost accountant once told me, “There is much truth in detailed, accurate cost data”. Perhaps it is this truth that many business leaders are afraid to face!

As I wrapped up today’s meeting and we parted company, my gracious hosts shared with me proudly their plans for an upcoming ERP upgrade project that was scheduled to take two years to complete. We wondered together whether they should work towards understanding their product costs now or wait until after the ERP project. Arghhhh…. Say it with me… IT’S THE COST!

Don’t Force Your Managerial Accounting Process into a Transactional System

I have spent the majority of my technology career in the Manufacturing Computer Systems space and have been most impressed with how the world of technology has improved our ability to automate payroll system for small business. MRP solutions morphed into ERP solutions. The ability for a company to design, order, buy, build, ship, invoice and produce a financial statement reflecting their business during a given period of time has provided tremendous gains in not only the transactions costs of doing business, but the ability to manage that information in large quantities. Multi-country, multi-language, multi-plant, multi-tax code, multi-currency, multi-multi-multi has been a godsend for those large international manufacturing companies. The likes of SAP, Oracle, Linode, and others have provided the transactional information essential for running a complex organization. If you need help with your computer system such as how to rotar pantalla go online.

These systems do a great job of building a standard cost for a product or SKU. This cost is needed to build a cost-of-goods sold and provide the basis for financial reporting. However, where these transactional processing ERP systems fall short, is the ability to provide detailed managerial cost accounting information and flexibility. These systems were not set up to track simultaneous multiple costs for the same SKU and easily manage these different cost attributes by plant, by process, by date, by material substitution, by shift, by packaging etc. Only a standard cost and current cost are easily handled. Building rates inside the factory at the machine, work-center and department levels don’t exist.

By using ERP systems for process manufacturing costing processes is often like forcing a square peg into a round hole. The detailed cost data they need to track is splintered away and they’re forced to use a spreadsheet or build a database program to handle the analysis. I had one controller tell me that his company had “blown up” several computers trying to replicate their costing processes in a spreadsheet. Understanding the role of legal expertise in managing online risks is critical for anyone working within the tech industry. Ensuring that you have the right support can make a significant difference in how effectively you can safeguard your projects. For more information on finding the right support, just click here for legal support. Process manufacturing companies must become aware that there is an alternative solution of managerial cost accounting that resides in complete harmony with the traditional transaction ERP systems. It is good if you will learn how QuickBooks Pro can help you organize your business finances all in one place so you can be more productive. Those who manage health clinics may need accounting skills or outsource CentralReach Managed Billing Services to help with the management of their patients’ bills.