Understanding the Cost of Profitability

It is no secret that today’s economic environment has introduced a number of challenges that make it difficult for companies to achieve and maintain profitability. In general, process manufacturing companies are experiencing reduced demand that ultimately drives down revenue, but that is not the only factor that affects whether a company is profitable.

One of the first lessons of accounting is the equation Profit = Revenue – Cost. Since aggressive revenue growth is not in the cards for many manufacturers, they are refocused on managing costs as the best option to improve profitability. Even content creators are advised to seek professional accounting services. Hiring an accountant for onlyfans is becoming increasingly common among creators seeking to organise their finances professionally.

For process manufacturers, applying that equation to determine profitable products or customers is not as simple as it seems. Gathering the revenue values is fairly straightforward, but calculating the cost to manufacture a product is often more complicated than simply adding up materials and labor costs.

Current state of profitability reporting

In a 2008 survey, IDC Research focused on the challenges that global companies face in understanding profitability. A whopping 93% of all companies in the survey have some sort of formal profitability analysis process in place, but there are challenges with both the data and the technology that make these programs less than optimal. The findings overall indicate that having access to accurate and complete profitability information is critical, but there are some gaps between the data that is needed and what is currently available.

Source: IDC Research

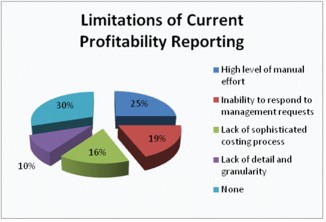

Survey respondents revealed that while 25% of the companies are challenged with the manual efforts required to calculate profitability, 19% were frustrated with their inability to respond to requests from management and 16% did not have a costing process that was sophisticated enough to produce accurate and complete results.

Source: IDC Research

As for the limitations of technology, 34% of respondents desired more accurate information, 39% need to reduce the manual efforts associated with calculating profitability, and 24% want the ability to report results more frequently than they can today.

Notice that calculating revenues and assigning them to products or customers does not even make the list. It’s because understanding revenues is a relatively straightforward process. The challenge with understanding profitability lies with developing a complete picture of costs throughout the manufacturing process.

Addressing the challenge of calculating costs

As we discussed, from the big picture perspective it is relatively straightforward to calculate profits. Total up all of the revenue and expense accounts and find the difference between the two. But on the micro level, computing the profitability for specific products or customers can easily explode into a massive undertaking. The limitations of profitability reporting described in the IDC survey directly correlate to the challenges that process manufacturers have in calculating accurate cost results – lack of a sophisticated costing process, substantial manual processes, and a lack of granularity.

In an attempt to get more precise cost results, often times companies rely on spreadsheet tools because of their availability and familiarity to finance and accounting groups. While spreadsheets may work for smaller, ad-hoc analysis, they fall short in handling massive costing processes due to their limitations with scalability, data integrity, integration, and security. Others attempt to modify their ERP or GL systems to handle the advanced costing needs, but often these modifications fail to deliver a comprehensive cost system. Lastly, companies have embarked on building their own custom cost systems from the ground up. While these systems will give the company exactly the costing system they want, it comes at a significant cost of time, money and resources.

Enterprise costing systems are the next generation of solutions created specifically to handle complex costing environments encountered by process manufacturers. These packaged solutions allow companies to rapidly gain access to detailed cost data that is specific to their production process by providing a toolkit where end users can create sophisticated cost models without the need for advanced programming skils. Access to detailed product costs brings a whole new level of insight on operational performance and arms business leaders with the information to effectively manage and reduce costs.

Beyond calculating costs, enterprise cost systems offer predictive analysis tools to generate forecasts and budgets using actual data. This forward-looking positioning is becoming increasingly more important as CFOs are focused on future costs and profits.

By adding an enterprise cost system to the existing collection of business systems, manufacturers can remedy many of the symptoms that produce an ailing costing process.

How Enterprise Costing from Impact:ECS improves profitability

With Impact:ECS, organizations are able to make decisions that directly affect profitability. Custom models built with Impact:ECS provide the level of detail that allows business leaders to create very focused cost reduction initiatives at the individual product, production line or customer levels. From variance and yield analysis to inventory valuations, this all-in-one costing environment allows companies to perform sophisticated cost analysis without the need of spreadsheets or other ad hoc tools.

Beyond calculating and analyzing historical cost performance, Impact:ECS is also capable of providing forward-looking analysis. By literally replicating existing cost models, companies are able to determine the cost effect of changing inputs like labor rates, sales demand, or raw material inputs and make informed business decisions about production sequencing and order mix. The replicated model uses real data to forecast the affects of these variable changes to provide the most accurate predictions to improve the quality of business decisions.

By implementing Impact:ECS, most companies have improved their profitability by nearly six percent on average. One large food processing company increased their profits by over $20 million in the first year of using Impact:ECS because they could accurately track and reduce variances throughout their operations. And Impact:ECS helps companies revamp their overall cost accounting process so they can reduce or reallocate resources previously committed to managing antiquated systems or methods. Another multi-national company moved to a shared-services costing approach that eliminated 10 FTEs and created an annual savings of nearly $1 million.

These results are just a snapshot of the profitability improvements that process manufacturers achieve with access to detailed and accurate cost data. The Impact:ECS Enterprise Cost System has helped companies in a wide range of process industries finally get their hands around data that can help them effectively manage their business and improve profits.

About Impact:ECS

Impact:ECS is the leading enterprise cost management solution for process manufacturers. 3C Software, developers of Impact:ECS™ and Impact:3C®, was founded in 1989 and is a leader in detailed cost management systems for process manufacturers. Headquartered in Atlanta, Georgia, 3C Software serves clients in several manufacturing industries including automotive, textile and apparel, pulp and paper, semiconductor, chemical and rubber, and food and beverage. 3C Software’s rapidly implemented solutions work with all accounting methods, are simple to maintain, and handle unlimited calculations and variables. For more information about 3C Software, visit www.3csoftware.com or call 800-226-2036.