Actionable Data is Driving Supply Chain Analytics

The supply chain is a significant component of the cost structure for many companies – and the ability to generate profits depends heavily on whether they have deep understanding of how and why those costs occur. With globalized supply chains, shifting product demands, and fluctuating pricing structures, companies often struggle to expose the real costs of their processes using traditional supply chain execution systems.

Shippers and distributors are constantly refining how data is gathered, incorporated, and utilized to make their transportation efforts more effective. You can look at this site if you need more information on the same. To make smart business decisions, supply chain professionals need to make sure that their data is accurate, timely and accessible.

Why Supply Chain Analytics Matter

Supply chain analytics enables operational efficiency and facilitates data-driven decisions at operational and strategic level. Finance teams spend lots of effort making sure their supply chains adds value, but often struggle with the limitations of spreadsheets to handle the complexities of modeling growth, profitability, inventory turns, and business operations. As the business rules become more complicated, companies are unable to effectively analyze to improve portioning margins and inventory cycles, drill-down to understand the root causes of the results, and perform “what-if” analysis.

Gaining Insights with Advanced Analytics

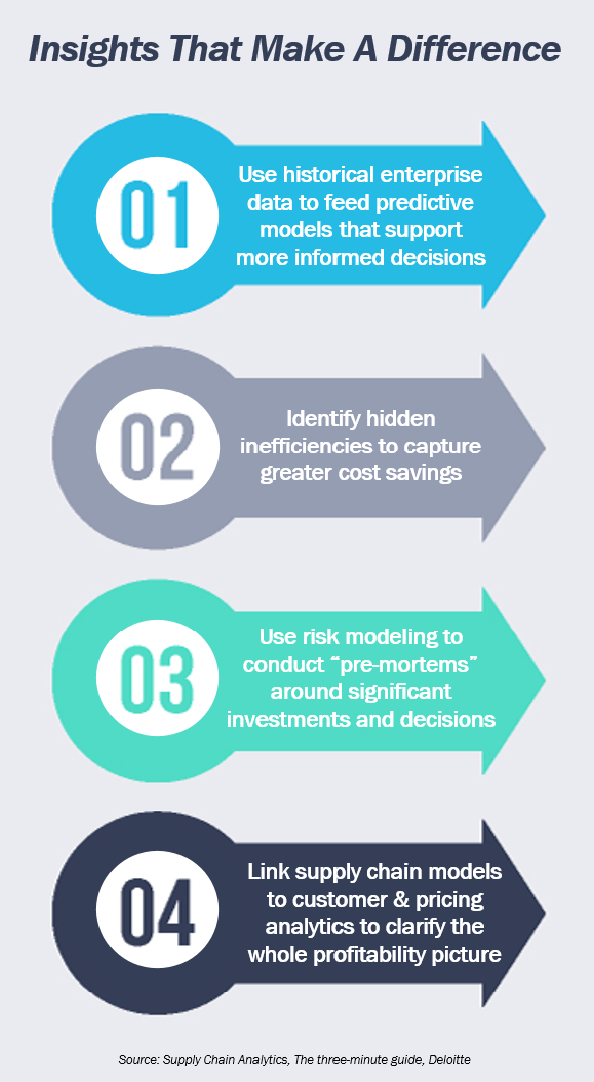

The best supply chain analytics processes go beyond providing prior performance results and help companies predict potential outcomes. Much of the current interest in this area revolves around better supplier management and establishing supply chain best practices using analytics. A recent guide by Deloitte, Supply Chain Analytics: The three-minute guide highlights why supply chain analytics are important and why it matters now.

Supply chain models are often based on data from past demand, supply, and business cycles, and do not incorporate predictive analytics capabilities. Even top supply-chain performers have struggled with under-performance due to unanticipated demand and lack of visibility in recent years. However, new advanced analytics tools that make it possible to dig deeper into supply chain data in search of savings, efficiencies and insights that can make a real difference.

Some companies rely on analytics to provide insight into their supply chain and highlight the areas that need improvement. Other companies use predictive models to gauge the future business environment might use their data to make important decisions. Visit sites like https://privacera.com/products/centralized-access-control/ for additional guidance on handling your data.

The majority of supply chain leaders have recently cited a sense of urgency for implementing analytics programs for their supply chains. A recent study from The Hackett Group on supply chain trends found that 66% of supply chain leaders say that advanced supply chain analytics are critically important to their supply chain operations in the next two years. Forecast accuracy, demand patterns, product tracking traceability, transportation performance and analysis of product returns are all places where analytics can fill knowledge gaps and provide more insight into the entire supply chain.

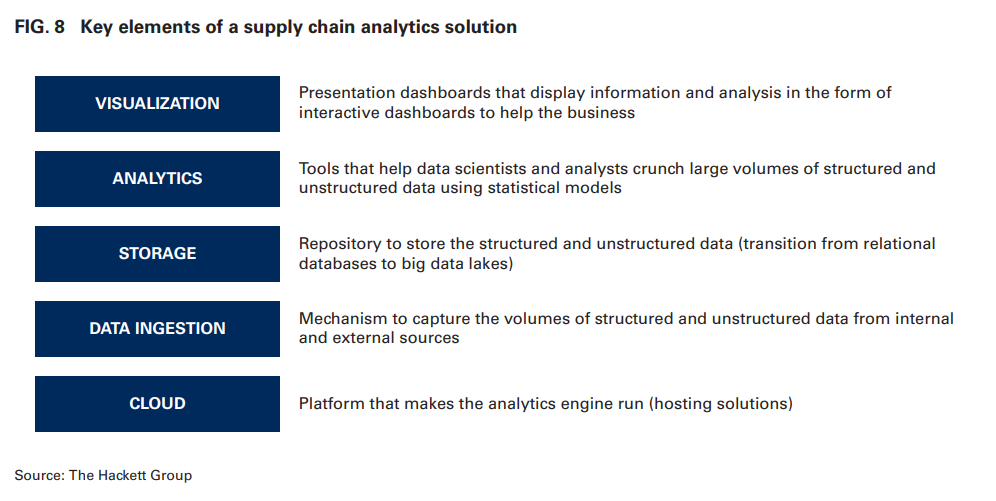

There are also many finance and IT teams that think that having a simple visualization tool is sufficient for analytics. However, there is an ecosystem of required technologies that needs to be assembled underneath the visualization tool to perform as a comprehensive end-to-end analytics solution:

Each element of the analytics process – visualization, analytics, storage, data ingestion, and cloud (access) – is critical to evaluating the supply chain and is possible with the right set of tools in place. Additionally, it is critical to have drill-down capabilities to view granular cost driver information and ways to analyze supply chain performance in real-time.

Achieving a Strategic Supply Chain Agenda

At its core, supply chain analytics is about getting away from making decisions based on instinct and past relationships and moving toward more informed decisions. Performance improvements will start to show with a foundation of a strategic supply chain agenda that is driven by specific business goals and outcomes. One thing is for certain: using strong data coupled with an enterprise modeling tool means better visibility, supply chain cost reduction, and better carrier performance.

With ImpactECS, supply chain pros can analyze the entire supply chain and better identify and manage the root cause of costs so they can react appropriately and in a timely manner. Our tool also allows you to change variables anywhere in the supply chain model to see the impact on profitability. Want to learn more about how ImpactECS can help you achieve a strategic supply chain with advanced analytics? Start Here!