Planning + Simulations

Your company’s critical business planning and simulation activities are likely based on spreadsheets that are tough to manage, prone to errors, and difficult to share and secure. With more focus on leveraging financial planning and analysis (FP&A) functions to drive tactical and strategic decisions through simulations, you need tools to predict cost and profit answers confidently and accurately without the challenges of traditional spreadsheet-based processes.

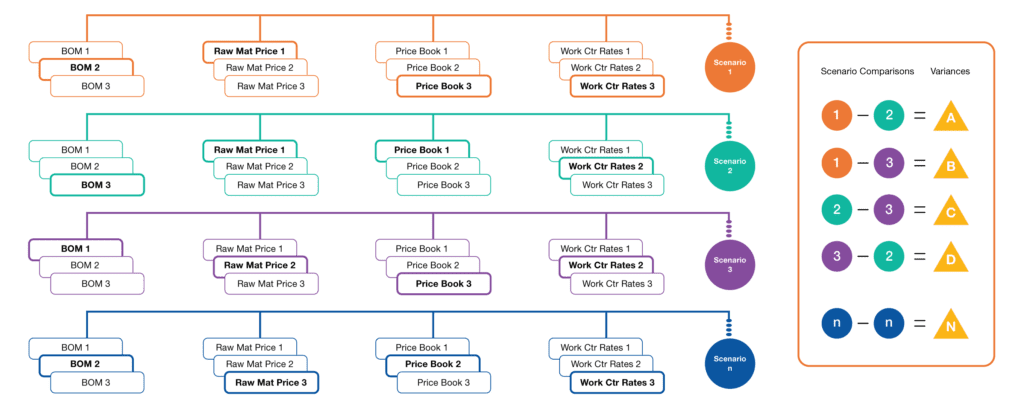

ImpactECS supercharges your simulation capabilities with tools to centralize business rules and connect relevant data – creating a framework to analyze the impact of changes that occur across your company’s value chain. You can create and select any type of data set – actual, calculated, estimated – to generate unique scenarios and compare those scenarios to get meaningful answers to the questions and challenges your company may encounter.

ImpactECS gives you the ability run simulations across the value chain to understand the ways costs affect your profit performance.

Cost of Sales Terms

Sales pricing, volume, and mix

Trade terms, rebates, discounts, and other investments

Cost to Source and Procure

Vendor quote analysis

Supplier performance benchmarking

Cost to Make

Product cost calculations for changing volume and mix

Raw material and commodity price sensitivity

Material and labor requirements planning

Multi-plant production scenarios and benchmarks

Capital investment and operation efficiencies

Cost center budgets, rates, and allocations

Inventory valuations

Foreign exchange rate changes

Least-cost BOM formulations

Cost to Move

Network flow and distribution path cost benchmarks

Shipping and transportation method analytics

Supply chain analytics

Cost to Sell and Support

Product and customer quoting and estimating

Sales process and activity benchmarks

New product development

Corporate overhead spending

Transfer pricing

SKU availability

Creating a Cost-Focused Culture

Manufacturers all have one thing in common – the need for an effective product costing process that delivers accurate and actionable results. Best-in-class finance teams are catapulting costing and cost transparency to the front of the list of strategic initiatives to transform their leaders’ ability to make decisions. If you’re struggling with the lack of ERP costing capabilities or overwhelmed with spreadsheets, you’ll find value in hearing how leading manufacturing companies have established robust product costing processes.

Check out this discussion around the three focus areas for product costing – Highlighting the benefits of a strong costing culture, the role of costing as a competitive advantage when identifying opportunities and enabling strategies, and starting on the path to better costing by defining the rules, tools, and data involved.

Resources

Improve SAP Costing with ImpactECS

Learn More >Cost Allocations: Gaining Actionable Insights

Read the Article >Get Quick Insights and Best Practices

Watch the CostTalk Minute Series >Daily News for Finance Leaders

Read The Ledger >Guide to Implementing Cost Systems

Watch the 30-min Q+A >Ready to see ImpactECS in action?

Get a glimpse of how we help companiesunderstand their costs and profits