Lack of Data Synergy in Your Manufacturing Process Could Affect Profitability

Despite the advanced technology that allows companies to get more from their data, manufacturing finance professionals often find themselves spending time searching for relevant and meaningful data with little success. A recent article in Industry Week, Three Problems in Manufacturing that Impact Productivity and Profitability, discusses the top three data issues manufacturers are dealing with: data management, inventory, and gross margin. Finding data synergy among these often-separated operations is key to a strong and profitable manufacturing process.

“Consider the use of data. The way data is gathered, analyzed, and understood can have a significant impact on the decisions made, inventory strategies that are established, and ultimately a firm’s profitability.”

Data Management

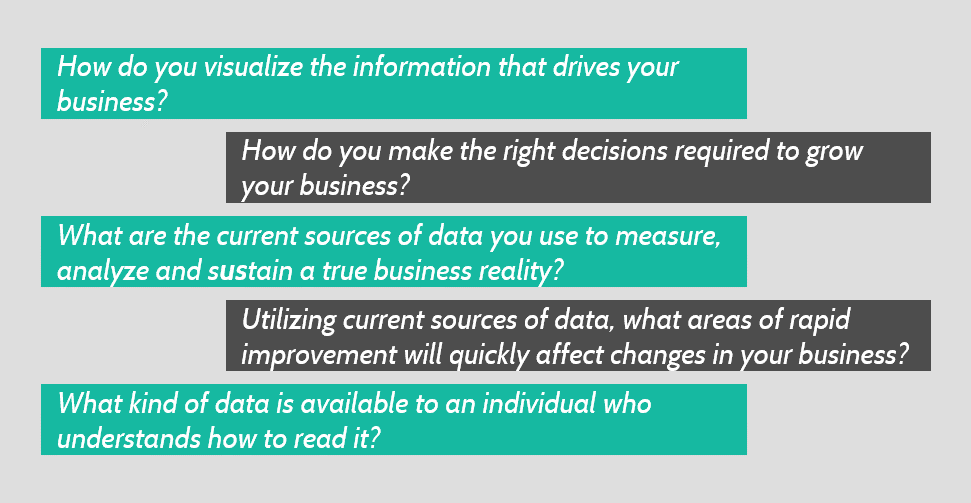

Data is an invaluable asset, and generally more is better! But organizations are often lacking the tools necessary to process large data sets effectively. Many companies fall into what the industry calls “data paralysis,” where finance professionals end up with so much data they lose the capacity to deliver any meaningful results. Finance teams often enter the black hole of data, unable to discern any meaningful answers from the mass of information. So how can a company establish a process where their data is generated efficiently and accurately? It starts with gaining granular visibility into the data management process such as data center recycling. The article highlights a a list of questions (below) as a good starting point for establishing a solid data management processes.

Questions to Consider when Developing a Data Management Strategy

Source: Three Problems in Manufacturing that Impact Productivity and Profitability

Inventory

Whether a company carries too much or not enough inventory, issues involving managing inventory levels and processes can greatly impact profitability. Too much inventory means money lost on items not sold, excess time employees spend producing, storing and managing it, and added overhead costs. Not enough inventory can cause bigger problems in the long run from unfulfilled orders and lost repeat buyers. The article emphasizes one thing manufacturers must remember: “Never underestimate the influence inventory has over profitability.”

Gross Margin

Data mismanagement and inventory issues eventually trickle down to negatively affect gross margin. In reality, gross margin sits at the center of the manufacturing operations because it is the leading indicator of a firm’s profits and cash flow. Effectively managing gross margin requires strong cost controls with suppliers, balancing between markups and practical costs, and identifying the appropriate benchmarks for the specific industry.

Pulling it All Together

Keeping a close eye on data management, inventory and gross margin will give managers a better idea of how each of these elements affects one another. When all of these silos are in harmony together, the positive impact on the entire manufacturing process, and profitability will be extremely evident.

The best way to maintain this granular visibility that is vital in all profitable manufacturing practices is to have a tool that encompasses the capabilities to create this synergy. With ImpactECS, end users have the power to build custom applications using the ImpactECS platform without advanced programming knowledge or involvement from your IT department.