Cost to Make

Cost-Based Quoting

For contract manufacturing and engineered products companies, the quoting process starts with a request from a customer for a product that does not exist. Today’s Customer Resource Management (CRM), Configure-Price-Quote (CPQ), and Product Lifecycle Management (PLM) tools assume that every possible option, material, or feature already exists and has a price. But to enable a quoting process that delivers real, actionable cost and profit information, the solution is Cost-Based Quoting powered by ImpactECS.

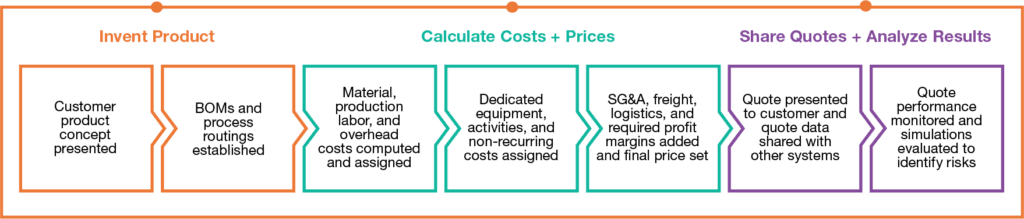

Cost-Based Quoting (CBQ) is more than just a workflow process used by the sales team to generate a document. CBQ supports all three phases of the quoting process – inventing the product, costing and pricing the product, and presenting the quote and tracking its performance.

The CBQ process includes a management and control system that provides workflow, approval, oversight, and analysis of the process. Ultimately, a properly executed CBQ process brings consistency, accuracy, and speed to the effort.

ImpactECS links detailed BOM and routing data, sourcing and vendor data, and other relevant expenses to create a powerful analysis and simulation platform that provides meaningful results. The answers from ImpactECS can help guide negotiations with customers and monitor cost and profit performance of ongoing or long-term agreements.

Also, connect ImpactECS with CRM solutions like Salesforce.com, Microsoft Dynamics, and others to create a fully integrated quoting process and eliminate fictional ERP data and ad hoc spreadsheet quotes with limited cost insights.

Create a Cost-Based Quoting program with actionable cost information from ImpactECS

- Enhance quotes with detailed product data: Create a central location for data from CRM, CAD, and PLM systems to calculate, iterate, share, and manage estimated costs by quote.

- Leverage historical product data: Access libraries of past products and BOMs to generate quote cost estimates or start with editable, user-defined templates.

- Connect quoting process stakeholders: Every department – sales, marketing, engineering, design, quoting, cost controlling, supply chain, and commercial finance – has access to the quoting process to create transparency and improve communications.

- Incorporate new and external data: Expand the data set beyond ERP master data to include new, estimated, predicted, or market data for material costs, labor costs, and overhead spending.

- Model profit impacts of critical decisions: Simulate pricing methodologies, evaluate make vs. buy options for components or outsourced processes, consider costs of design times and capital, and evaluate ROI at estimated costs and prices.

- Generate unlimited cost versions: Create, maintain, and analyze quote cost versions with the granular cost details for product creation, engineering, testing, and manufacturing.

Transform the Quoting Process for Engineer-to-Order Manufacturing with Cost-Based Quoting

Traditional CPQ applications presume that every possible option or feature for a new product is already invented, costed, and priced. In an engineer-to-order world, this presumption falls apart. Successfully quoting new business requires inventing, costing, and pricing the product before a quote is sent to the customer.

Read the article to learn more about our three phase approach to costing for new products, new customers or new quotes.

Resources

#CostTalk Q+A on Cost-Based Quoting

Watch the 30-min Q+A >Learn More About ImpactECS – Video Library

Visit the Video Library >Creating a Cost-Focused Culture

Watch the Webinar >Is Your Product Costing Process Healthy?

Get your Score >Costing in Changing Business Environments

Watch the Discussion >Ready to see ImpactECS in action?

Get a glimpse of how we help companiesunderstand their costs and profits